Quality is one of the regular words we hear every day. Everyone wants to be associated with quality in every aspect of their lives. We want it to reflect in all the products we use, from our shoes and wears to cars and gadgets and even our kitchen utensils. The concept of quality extends to the buying and selling space.

Sellers want to charge more for their products because they are of the best quality. However, as the buyer, the onus is on you to fact-check these claims, perhaps by reviewing the product’s datasheet or checking out feedback from previous buyers of the same product.

You are essentially doing these findings to find the right answers to these two important questions:

Is the product having the right qualities?

Can the product meet your needs?

Every organization that is serious about being successful must prioritize quality. Whether you are offering services or manufacturing products, quality outputs can be the distinguishing factor between you and your competitors.

So, how will you define quality, and why should you look out for quality in every aspect of your daily life? Read on to find answers to these all-important questions about QUALITY in this article.

What is Quality?

The meaning of quality can be relative. According to the ISO 8402, which dates back to 1994, quality is “the totality of characteristics of an entity that bear upon its ability to satisfy stated and implied needs.”

Putting this more simply, we can only declare that a product has a good quality when it meets the requirements and expectations of the end-user or client.

We can also define quality as:

- Focusing on meeting the needs of customers;

- Adhering to the original purpose; or

- Meeting specified requirements

These specified requirements are found in a specification – a document showing the requirements with which the service or product has to meet.

Any organization that wants to ensure quality can achieve this by adopting these three levels of activities in the order listed below:

- QM

- QA

- QC

Let’s discuss each of these levels extensively.

Quality Management

Also known as QM describes the effective oversight of all tasks and steps involved in achieving and sustaining the desired result. It often entails the implementation of a quality policy and the creation and adoption of other vital components such as;

- Planning

- Assurance

- Control

- Improvement

The goal of Quality Management is to put out only quality services and products to the end-user while ensuring the availability of necessary tools to implement changes in the processes and systems. The effective implementation of these changes will lead to products and services of superior quality.

Quality Management is a failsafe way of ensuring consistency in a product, service, or organization (Wikipedia). Therefore, QM revolves around the development of the delivery of quality services and products.

Unlike services, products are tangible deliveries and are easily assessed. Hence, it is easier to keep track of the quality management of products. The quality of a service is often subjective; it is largely determined by the quality of the relationship between the stakeholders involved in the process, including the customers, service providers, distributors, and others.

Here is an article that offers more insight on Quality Management.

Quality Assurance

Also known as QA, is that aspect of quality management that ensures that the specified quality requirements will be met. Quality assurance is often defined as “all those planned and systematic actions required to provide adequate confidence that a product, service, or result will meet the given requirements for quality and be fit for use.”

Quality assurance has multiple components, including:

- System setup

- Quality manual

- Training

- Standard operating procedures

- Assigning a QA Manager

- Auditing and Verifying Compliance

- Quality Assurance Maintenance

QA develops and sustains set criteria for manufacturing quality products. The role of a quality assurance system is to improve the credibility of a company and the confidence of customers in their products. It also enhances work processes and overall efficiency, ensuring the company is better positioned to outperform competitors.

You can learn more about Quality Assurance in this article.

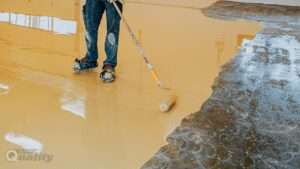

Quality Control

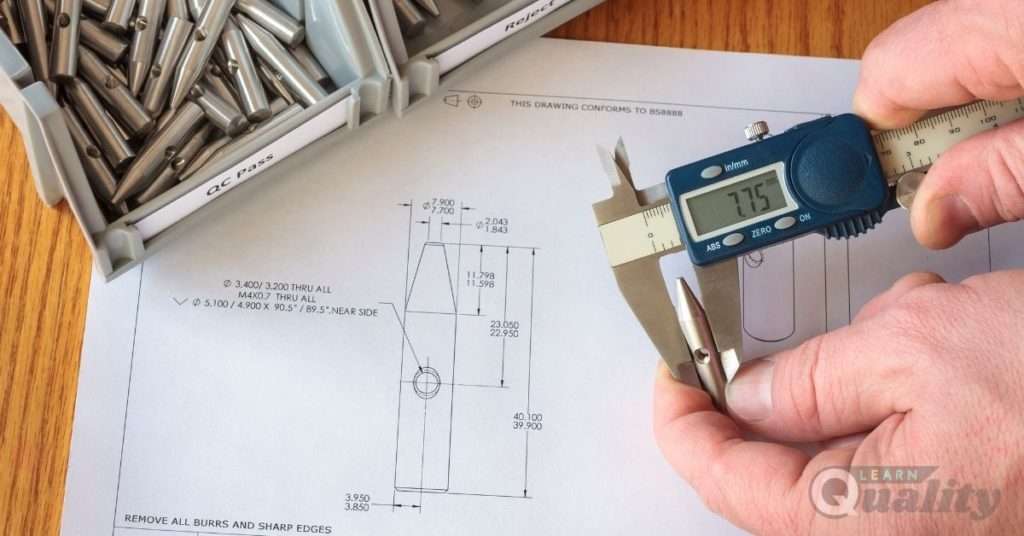

Also known as QC, can be defined as the “operational technique and activities used in fulfilling the requirements for quality.” According to ISO 9000, QC is “a part of quality management that centers on fulfilling quality requirements.”

One of the crucial aspects of QC is Inspection. Inspection refers to a group of activities, including measuring, examining, testing, gauging one or multiple features of a product or service, and ensuring they conform to the specified requirements.

The basic description of Quality Control will be the inspection, testing, or assessment of the features of a product to ensure maximum conformity to the specified requirements. QC aims to determine if any non-conforming characteristic can be fixed or removed before the product advances to the next level.

If a product or service has a characteristic that does not conform to the specified requirement, it becomes a non-conformance service or product. And the only way to restore conformity is to implement the necessary preventive and corrective actions.

Quality Control Inspectors or Quality Controllers undertake all the necessary inspection and quality control tasks that determine the conformity of a product. These professionals are specially trained in this field and are duly certified to handle such responsibilities.

Readout More on Quality Control in this article.

How best can we define quality?

While there are various descriptions of quality, the most popular defines quality as the “conformance to the specified requirements.” A product or service can only satisfy a client’s needs or end-user if it conformed to the specifications.

What does quality mean?

Quality means serving customers with innovative products or services with the expected features and zero defects so that it is in the best condition for use.

What is the full meaning of quality?

The Cambridge Dictionary defines quality as how good or bad a thing is. Here are some sentence examples:

- The shop sells top-quality kitchen appliances.

- That food is of a poor or low quality.

- These wears are from a global brand known for supplying quality products that last longer and look great.

- The television is incapable of displaying HD-quality pictures.

Why should organizations be concerned about quality?

Providing quality products is one of the ways to ensure customer satisfaction and commitment. It also helps the business avoid replacement costs on faulty products.

A company is at the risk of harming their reputation if they are at the center of product failure or poor-quality products that leads to product recall campaigns. Therefore, ensuring quality is important for businesses.

Who determines what high quality is?

Quality is dependent on a set of requirements. However, quality is assessed when this set of requirements is compared with a set of inherent features of the products.

A product is considered excellent (in terms of quality) if those inherent features meet the requirements. It is a case of low or poor product quality if the features do not meet the requirements.

How do organizations achieve quality?

Quality is achievable by implementing the three levels of activities below:

- Quality Management

- Quality Assurance

- Quality Control

Why should we be concerned about quality?

As an organization, an important requirement for success is always to pursue better quality. There are several benefits of effective quality management, including an improved brand image and reputation, insulation against risks, improved efficiency, more profits, and better chances of overall improvement.

As an individual, a lackadaisical attitude towards the quality of a product or service we receive can lead to:

- An irredeemable product failure

- Spending heavily on product repairs and replacement

- Physical harm while using the poor-quality products

- Irreversible loss of money and time due to the receipt of poor-quality service from a business or individual

Is a defective product the same as a defect in the product?

No, both are different situations.

A defect is an imperfection, a deviation from the norm. There are large or small defects, both capable of making a product unusable or usable only outside the required specifications.

Conversely, a defective item doesn’t perform as expected due to the presence of one or multiple defects. However, an item with a defect is not defective if it performs as expected.

For instance;

A page in a book containing a typo is a DEFECT, but a book falling apart when picked up is a DEFECTIVE PRODUCT.

A customer ordering a burger with tomato but getting a burger without tomato is a DEFECT. However, if a burger patty is undercooked and unhealthy to eat for the customer, that is a DEFECTIVE PRODUCT.

RELATED ARTICLES

17 Quality Control Information You’ll Ever Need

How Quality Assurance Can Ease Your Business Pain

RELEVANT TRAINING COURSES