How to Perform the Chloride Test following ISO 8502-5

The chloride test is one of the most common tests performed on the surface to be coated as well as the abrasive used to prepare the surface for coating. Chloride is one of the salts that are commonly found in water and are referred to as water-soluble salts.

When the salt exceeds the acceptable limit on the surface and a coating is applied, the coating fails, because soluble salts are known as corrosion accelerators. The most typical issue that soluble salts develop following coating application is osmotic blistering, which disbondment the coating from the surface and causes it to fail prematurely.

Types of soluble salt?

The three most common types of salts that cause significant damage to the coating are as follows.

- Chloride (C)

- Sulfate (S)

- Nitrate (N)

Are the chloride and salt tests the same?

Both the chloride and salt tests are different tests with separate test procedures or standards that must be followed in order for the test to be performed. The overall presence of the salt is determined by testing according to ISO 8502-6/9, which means the result is a combination of chloride, sulfate, and nitrate.

However, if we wish to determine the presence of a specific salt, such as chloride, on a surface, we can utilize the test method as described in ISO 8502-5.

Test Methods for measuring the water-soluble salt

The industrial specification recommends carrying out the soluble salt test in general or specifically using the standard test method ISO 8502-6/9, ISO 8502-5, or SSPC G15 as part of the surface preparation.

This article is going to teach you how to measure CHLORIDE on a steel surface that has been prepared for coating using the CHLOR RID test kit and the ISO 8502-5.

Principle of the Chloride Test

Controlled washing or immersion in water removes a small amount of the water-soluble chlorides on the test substrate. The collected sample is tested to determine the chloride ion concentration, which is indicated by a change in color in a silver chromate detection tube (titration tube)..

What are the requirements for the chloride test?

The chloride test necessitates the use of the following apparatus:

- Water with a purity of at least grade 3 according to ISO 3696.

- Titration tube for detecting chloride ions.

- Tube cutter to cut the detecting tube’s ends.

- A measuring cylinder with a capacity of 250ml.

- Beakers, one with a capacity of 100ml and two with a capacity of 250ml.

- Stirring rod made of glass.

- Cotton gauze, approximately 300mm × 300mm, free of chlorine.

- Rubber or plastic Gloves.

- A tape measure

What precautions should you take during the chloride test?

The tester (typically a coating inspector) should cover his or her hands and eyes while performing the chloride test. He or she should not use his or her fingers to touch the thin ends of the glass titration tube since salt from the skin will create reading inaccuracies.

After the chloride test, thoroughly dispose of the test tube in accordance with local rules.

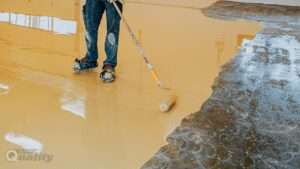

How should the chloride be extracted from the surface to be tested?

- Remove the cap and pour the whole contents of the CHLOR*EXTRACT solution bottle into the test sleeve. When applying to a horizontal surface, clip the sleeve to avoid solution loss and remove any excess air.

- Remove the blue pressure-sensitive backing from the test sleeve; squeezing between fingers and thumb removes the air from the test sleeve. Apply the test sleeve firmly to the test surface.

- To allow the extract solution to come into contact with the test surface, lift and hold the free end of the test sleeve upright. Massage the solution through the test sleeve against the surface with the other hand for 2 minutes.

- Remove the test sleeve once the massage is complete.

How can the solution in the sleeve be prevented from flowing down to the horizontal surface?

- The solution will flow down to the closed end of the test sleeve for vertical or overhanging surfaces. To transport the solution to the closed end of the sleeve before removing it from horizontal surfaces, press and slide the finger across the sleeve. Use the clip to keep the solution in place while removing the sleeve.

How do I use the titration tube to test the chloride level?

- Remove the tube from the kit and, taking care not to contact the ends of the titration tube, break off both ends with the metal snapper provided with the kit.

- Insert the titration tube with lower numbers and an arrow at the bottom into the test sleeve.

- Insert the sleeve containing the extract solution and titration tube into the previously made hole in the box lid. Wait 1.5 minutes, or until the solution has risen to the top of the titration tube.

- Remove the titration tube immediately and read the number on the titration tube at the interface of the color change to get one of the following: Pink represents normal, while white represents the chloride level.

What should you do if the chloride level exceeds the limit?

The chloride level can be reduced by washing the entire area to be coated with portable water. Following the water washing, the chloride test must be repeated to check that the level is reduced and meets the specification requirement.

What is the unit of measurement for chloride tests?

The tube provides the reading in the two units listed below.

- µg/cm2

- Parts per million (ppm).

Conclusion (Chloride Test)

The chloride test is a type of salt test that can be performed in accordance with ISO 8502-5. The test is used to check for the presence of chloride on the surface as well as on the abrasive to be used for surface preparation or abrasive blast cleaning. Coating inspectors typically undertake this test before coating application and after the surface preparation. The chloride test, commonly known as the surface cleanliness test, confirms the cleanliness of the surface following blast cleaning.

More Articles Related to Painting and Coating Tests

Training Courses Related to Protective Coating/Painting Inspection and QA/QC