We all know that quality and inspection are one of the important components of the quality management system and play an important role in establishing a business.

Businesses flourish only if they provide quality products to their customers. Customer satisfaction is really necessary for taking a business to heights because the trust that good quality products can build with a customer is priceless.

Quality ought to consistently be a top priority for running any organization. At the point when it comes down to things related to complex designing items, the primary concern that any organization ought to consider is to set the desired level of quality based on the customer and/or end-user need.

The businesses design the quality system in a way that touches every aspect of the work area, the two most common aspects to consider primarily are;

- Materials

- Equipment

1. Materials

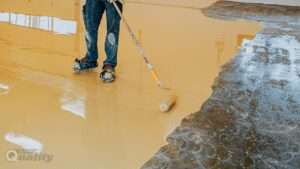

Any material or components that will be used to manufacture a product first need to pass the inspection and quality control test to ensure they meet the specified requirements.

Businesses must follow a trend to discard the unspecified or damaged material to process further in the very beginning while carrying out the inspection as soon as a procured material arrives at the job site.

Material storage and handling is other important considerations that any business must take into account following the product datasheet and material safety datasheet.

Often a material has its set shelf life within which the material needs to be utilized, so the material storage requires FIFO practice to get rid of material expiry issues.

2. Equipment and Calibration

Another crucial aspect for the business is the equipment, that helps manufacturing the product, which must comply with the necessary requirements to achieve the desired result and/or to produce the quality product. Equipment calibration is one of the important aspects that ensure if equipment will perform its intended function.

Often such calibration is done by the equipment manufacturer. A calibrated equipment or instrument receives a calibration certificate that state the method used for the equipment calibration and the calibration validity.

Once the calibration validity is expired, the organization’s responsibility is to re-calibrate the equipment following the equipment’s manufacturer guidelines. This can be done by contacting the manufacturer for the calibration or appointing a third-party calibration agency.

The organization must also keep a calibration record and monitor the equipment’s calibration status regularly to ensure the calibration set date is not elapsed, or the equipment is not used once its calibration is out of date.

Inspection and Quality Control Process

An organization could only survive in the market if they are bringing good quality products on shelves. Otherwise, it only takes days for businesses to fail in the market.

The quality control system, when implemented appropriately, permits the organization to establish if an item that the business is going to produce will be worthy for customers or end-user. The components that include but not limited to achieve this requirement are as follows:

- Documented reviews

- Calibration

- Inspections

- Testing

- Reporting

- Corrective actions

- Preventive actions

These components give the business the benefit of making a quality product and helps them improve continuously.

Inspection and Quality Control Services

With the increasing demand for quality and inspection, it is more competition now. Hence, many organizations in this work era nowadays, have stepped into the market to provide inspection and quality control services.

These organizations make use of cutting-edge technology. Along with it, the resources that come in the presence of a competent team of professionals help to create the best product. The professional quality and inspection companies provide plenty of services, that includes but not limited to the following:

- Drawing and/or specification review

- Third-Party Inspection

- Design evaluation

Options for the Inspection and Quality control tasks

Furthermore, if we look thoroughly in the market, many organizations still perform the needed quality control tasks independently.

In most cases, contractors or manufacturers do have their own quality control team, however, their client and/or end-user assign third-party inspection companies at their facilities to carry out inspection and quality control tasks on their behalf.

The third-party inspectors collaborate with the quality control team of the organization who produce products for the client to carry out the specified inspection and quality control tasks. The third-party inspectors then produce reports based on their findings and report to the client directly.

Generally, the external third-party services give an unbiased opinion, and the case is the same with the quality control system as well. The agencies give honest feedback and that helps their client to prevent the arising and occurring problems. After the criticism, the maker finds approaches to improve the nature of items.

Why Inspection and Quality Control is Important

Undoubtedly, the quality control and inspection mechanism is a rewarding practice for businesses. It doesn’t matter whatever the nature of your business is, the quality control professionals always lend a helping hand.

These days, quality is definitely of utmost importance to customers. Customers usually choose the one brand that has good feedback. Additionally, cutting-edge clients know precisely what they need.

So, if you are running a business, and customers complain about your products, you may lose customers. The products that do not meet customer requirements normally don’t take time in vanishing from the markets.

The manufactures must carry out a product inspection periodically. Because this can help them know the reasons for the reduction in sales. This can happen because of:

- The source of their materials

- Sometimes, the production process is deviating the set guidelines

The manufacturers should regularly check the quality of their products because even the smallest problem can hurt their business reputation.

Obviously, no businessmen like the quality to suffer, but, sometimes technical glitches can happen. This makes it essential to perform a quality check so that you can stay away from unfavorable circumstances.

Hiring a Quality Control Inspectors or Agencies

If you find it difficult to do this on your own, you can always count on quality control agencies, or hire certified quality control inspectors. Such organizations have a quality controller who has undergoes specific quality control training and gets certified to carry out inspection and quality control tasks of a specific work (discipline wise).

The inspectors can watch over your manufacturing processes and can help you with improvements. Good professionals closely scrutinize each small detail and provide the best advice to improve the whole process, ultimately leading you to build a more efficient process.

The whole process boosts your business to grow. Although, it’s an extra investment, hiring the services of a quality control organization or appointing a certified quality control inspector is definitely a worthy investment.

A business that relies and focuses on the inspection and quality control achieves great results. The team of workers obverse or test a set number of products and if the products are not achieving the company’s standard, the quality control team reports and seek corrective and preventive actions.

As well as, the quality control team often can stop production until the full investigation completes. The quality control team and or personnel is there for you always to make sure that you bring the best to the market until the company rectifies the existing issues.

An efficient quality control system is a must if you want to give the best quality to your customers.

RELATED ARTICLES

17 Quality Control Information You’ll Ever Need

How Quality Assurance Can Ease Your Business Pain

RELEVANT TRAINING COURSES