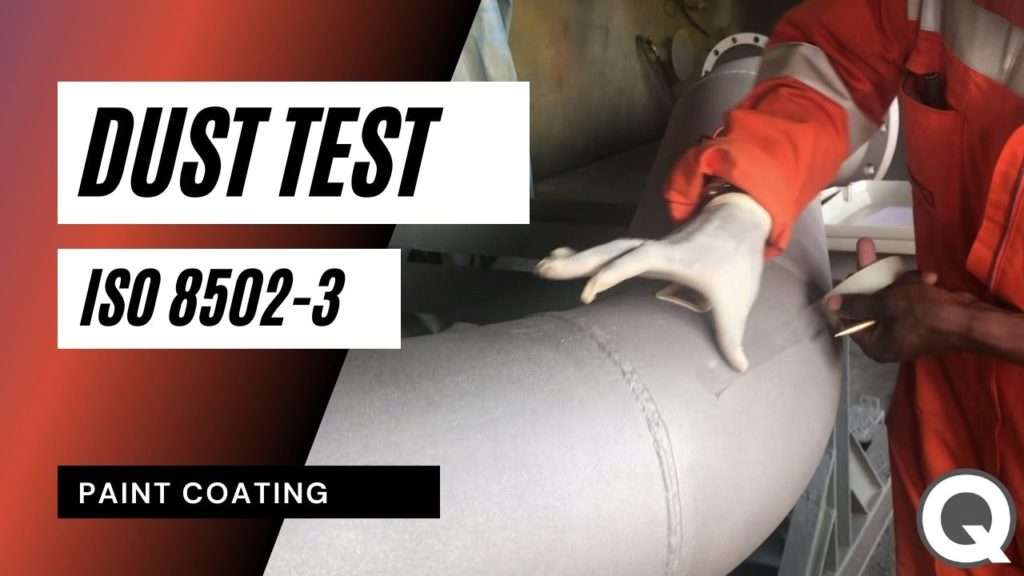

Adhesion is one of the major common problems of a protective coating or painting which often causes premature coating failure. One of the mediums that coating can have adhesion failure is due to the dust particles available on the surface while the paint coating application, thus the coating specification often specifies to carry out the Dust Test or Dust Tape Test after the surface preparation and before the coating application.

The specification sets the limit of the dust level and the coating inspectors perform the dust test following the specification guidelines to ensure if the prepared surface contains dust on it and/or the dust level is within the specified limit set by the coating specification.

Often dust is invisible to the naked eyes and may not be detected by the visual inspection.

When talking about dust, it’s made up of fine particles that can be easily deposited on a prepared surface due to the following sources:

- Surface preparation operation through blast cleaning

- Soil that gets lifted through the wind

Dust particles get easily accumulated on horizontal surfaces, in structural cavities, and the inside of pipes.

This article will make you learn all you need to know on performing the dust tape test before you apply coating on the prepared surface.

The Main Issue of having Dust on the Surface to be Coated

Dust particles found on blast-cleaned steel surfaces might alter the adhesion of the coating that’s applied. Also, the absorbed moisture can increase the chances of corrosion of this steel surface.

For project coating specification, it often requires a dust test to make sure that the surface for coating is properly cleaned. It should also be free from all dust particles prior to the coating application.

The Dust Test Methods

According to a trend in the industry, a pressure-sensitive tape test is carried out that follows industry specifications plus the applicable standards. Generally, a project coating specification will often specify ISO 8502-3 standard test method in order to perform the test.

The tape test will require a kit, like from TQC, Elcometer, or approved equivalent so it’s used by the coating inspector. The kit contains the following items:

- Display board

- Dust assessment plate

- Spring-loaded roller

- Disposable gloves

- Adhesive tape

- Magnifier

- Pictorial references

The Dust Test Procedure

Prior to the test, the coating inspector should get rid of the first three turns of adhesive tape from its roll. They should then take out a 200 mm long piece. Touch its end to hold the tape, and then firmly press it 150mm onto your surface under the test.

Now you have two options for your next step:

- Take your thumb and keep it across one end of your tape. Move your thumb, while keeping your firm pressure, at a constant speed right along with your tape 3 times in each direction. Hence, each stroke will take between five to six seconds.

- Use a calibrated spring-loaded roller and apply it centrally across one end of your tape. Then move the roller, while keeping a downward load between 39.2N – 49.0N at a constant speed right along with your tape 3 times in every direction. Hence, each stroke takes between five to six seconds.

After performing one of the above-mentioned tasks, now remove the tape from your test surface. Keep it on your dust assessment plate that comes with the kit. Make sure that the tape properly sticks on the plate. You can also use your thumb to stick it appropriately.

Assessing The Dust Quantity

Once on the assessment plate, carefully compare the section on the test strip with your equivalent section from the pictorial reference that’s provided. Compare the two thoroughly before rating it. You can rate it between 1 to 5.

Assessing The Size Of The Dust

Use a magnifier to examine the size of the dust particle on the tape which gets designated in the pictorial reference. You can rate the size between 0, 1, 2, 3, 4, and 5.

Specification Compliance

The inspector’s job is to record these findings within the daily report. They should take help from the project coating specification to make sure that the dust size and quantity is within the right range.

What To Do If Dust is Not Within The Specification

In this case, the dust should get blown from the surface by using dry and clean compressed air. You can also use an air blower. After it’s cleaned, the test should get performed again to make sure that the level has decreased to the specified limit.

Applicable Standard for the Dust Test

To perform the test in a better way, the inspector must always refer to the applicable standard referenced in the project coating specification. ISO 8502-3 is one of the common standards often specifies in the specification.