Corrosion, also known as rust, is the orange-brown color that appears on the metal surface when it comes into contact with the atmospheric elements. Most of the people in the world have experienced such discoloration on the metal surface but they might be unaware of why this happens and if it causes any problem to the metal.

This article will answer most of the questions that you may be having on the corrosion of steel.

Corrosion Definition

Described as the deterioration of metal due to chemical reactions between the metal and the environment. The reaction between the metal and its environment starts as soon as the water and the oxygen in the environment come into contact with the metal. The water acts as the electrolyte for the rust to start on the metal surface.

The extent and type of deterioration due to corrosion depend on the metal type and the environmental conditions where the metal is exposed to.

The Nature of the Metals

Metals in their natural forms are found as ore, extracted from the ground through mining, then processed to make it useful for various purposes.

The extracted Metals from the ground are divided into two categories, i.e. less noble (i.e. ignoble) and nobler. Ignoble means a material can react with its surrounding environment when exposed to it.

Almost all metals are prone to corrosion attack, due to their tendency to react with the surrounding atmosphere, but the rate of rusting differs based on the metal’s nobility. For instance, mild steel or carbon steel is less noble than stainless steel, thus the rate on mild steel is faster than stainless steel.

Why stainless steel corrodes slowly is that it is a combination of metal and other alloys, this combination makes the stainless steel nobler than mild steel, and this is why we often prefer it to other available metals like mild steel.

Some other small groups of noble metals like silver, gold, platinum, etc. are less reactive to the surrounding atmosphere and are the only metal we use in their pure form, these metals rarely corrode; hence they are usually more valuable when compared with the other alternate metals and are very costly.

Some other small groups of noble metals like silver, gold, platinum, etc. are less reactive to the surrounding atmosphere and are the only metal we use in their pure form, these metals rarely corrode; hence they are usually more valuable when compared with the other alternate metals and are very costly.

There are various causes of metal corrosion. Some of these causes can be prevented by combining pure metal with alloys. In other cases, a strategic combination of metals or the effective management of the metal’s environment can also prevent it.

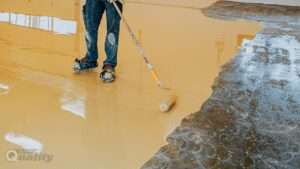

Application of the protective coating on the metal surface is also an effective way to reduce rusting.

Here are the 2 common forms of corrosion

General

General

This is a common type of corrosion that attacks the entire surface of a metal structure. This type of corrosion occurs on the metal due to electrochemical or chemical reactions.

When this happens, the metal thickness eventually reduces to a point where the metals break down or fail to perform an intended work. This form of corrosion is predictable, so it is easy to plan and manage the attack.

Localized

As the name suggests, this type of corrosion attacks specific parts of a metal structure. It comes in three different forms and may cause catastrophic failure of a structure or equipment.

Pitting, which occurs on the localized area and creates small holes in the metal surface.

Crevice, which occurs on a metal surface at, or immediately adjacent to, the gap or crevice between two joining surfaces, including the hidden areas under gaskets.

Filiform corrosion, also known as under film corrosion, is a special form of corrosion that occurs under some thin coatings when water penetrates a coating.

Galvanic Corrosion

Commonly termed as bimetallic or dissimilar corrosion, takes place when there are two different metals connected in an electrolyte. When this happens, one of the metal which is less noble than other become the anode and start corroding, however, the other metal which becomes nobler being unaffected from it.

We hope you now have understood what causes corrosion, and now, might be looking forward to knowing how to prevent the it? Please read out our next article related to this topic.

RELATED ARTICLES

17 Quality Control Information You’ll Ever Need

How Quality Assurance Can Ease Your Business Pain

RELEVANT TRAINING COURSES

QA/QC Coating Inspector Courses