Advantages and Disadvantages of TSA Coating for CUI Prevention

Corrosion is one of the most common problems that steel faces. While there are numerous techniques to protect steel from corrosion, thermal spray coating is a metallic coating that is frequently applied to steel to protect it against corrosion. While there are many more benefits of using TSA, one of them is that the TSA coating provides the best solution for CUI prevention.

This article will educate you about thermal spray coatings, how they are applied, and what their benefits and drawbacks are.

What exactly is TSA coating?

TSA, or Thermal Sprayed Aluminum coating, is a common anti-corrosion coating in the industry. TSA is typically required for thermally insulated substrates with only the purpose of preventing CUI as well as for steel aqueous corrosion protection.

TSA is also known as metalizing and it uses a variety of sacrificial coatings for corrosion protection, including aluminum, zinc, and a mixture of the two.

How is TSA coating applied?

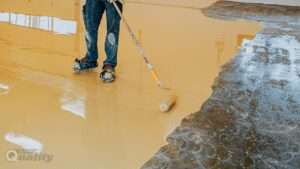

TSA applications involve using a powdered or wire form of metal that has been melted by an energy source and propelled or sprayed onto the surface of another metal or structure for corrosion prevention, wear resistance, traction, or dimension restoration.

What methods of application are used for TSA?

Despite the fact that there are different thermal spray application methods available, the two most popular and efficient methods of applying TSA coatings are.

- Combustion Wire Fed (flame spray) systems

- Twin Wire Arc systems.

Is the TSA the best coating for CUI prevention?

TSA is a tried-and-trusted corrosion barrier technique that is designed to prevent corrosion under insulation or CUI and to preserve the external surfaces of process pipework and equipment for long periods of time (more than 25 years).

TSA coating application and maintenance costs

A protective coating system applied over a surface typically costs the following:

- The overall installation cost

- The overall costs associated with system maintenance and inspection over the system’s entire life.

Choosing TSA as a corrosion-resistant protective coating can be more effective and cost-efficient than utilizing an organic coating. The total expenses should include the cost of:

- Surface preparation

- Coating application

- Field erection (if new equipment)

- Any additional expenditures if the field is used

- Inspection and quality assurance

- In-service inspection

- In-service maintenance

- Repair and/or replacement

What are the Benefits of Using TSA Coating to Prevent Corrosion?

The following are the primary advantages of using TSA coatings for corrosion protection over standard organic coatings.

- Longer service lifespan with minimal maintenance and inspection requirements.

- Best for CUI prevention

- Mechanical damage resistance.

- Temperature resistance is greater than that of organic coatings (from 100C to 500C).

- Steels are sacrificially protected in aqueous environments.

What are the Drawbacks of TSA Coating?

The following are the key disadvantages of TSA coatings over standard organic coatings.

- Application costs more. Field application difficulties.

- Operations and maintenance organizations are resistant to change.

Conclusion (TSA Coating for CUI Prevention)

TSA stands for Thermal Spray Aluminum coating, and it is one of the corrosion prevention solutions for steel that is subjected to aqueous conditions, such as insulation. The ideal option may be to use TSA as a coating system for CUI prevention.

Related Articles for CUI prevention

What is Corrosion Under Insulation

What is Protective Coating or Painting