This article discusses the most popular techniques used by coating inspectors for extracting and analyzing soluble salts on steel surfaces after it has been prepared for coating application. Because coatings applied to surfaces contaminated with soluble salts over an amount specified failed prematurely, salt testing is a necessary test that must be performed following surface preparation.

The extraction of the salt from the surface and the analysis of the solution are the two primary steps in soluble salt testing. The purpose of this article is to guide the reader in extracting and performing the test using the salt contamination meter (SCM).

Let’s get into the article and learn about the solution used for extracting the salt from the surface.

The Extracting solution used for the salt testing

Distilled water with a conductivity value of 5µS/cm is widely used as a solution for extracting salt from the surface. The coating inspector will check the conductivity range of the water, and if it is outside the limit, the water should not be used.

What exactly is a salt contamination meter?

The salt contamination meter, also known as SCM, is a hand-held instrument that does both sample extraction and analysis.

What equipment is necessary to testing the salt?

- High-purity test paper

- Magnetic paper positioning

- Salt contamination meter a bottle of purified water

- Tweezers

- A syringe

- Rubber or plastic gloves

Is it necessary to calibrate the salt contamination meter before using it or performing the salt testing?

The test is generally performed by coating inspectors, who must confirm that the soluble salt meter is in good working condition, that the calibration certificate is valid, and that the instrument accuracy is checked by performing onsite calibration in accordance with the instrument manufacturer’s requirements.

If the instrument’s accuracy is discovered to be outside the manufacturer’s limit, the instrument should not be used for the test unless its calibration has been corrected and found to be acceptable.

How should the salt be extracted from the surface to be tested?

- Put on a clean pair of disposable gloves.

- Fill the syringe exactly with 1.6ml of high-purity water.

- Remove filter paper from the pack with tweezers and set it on the magnetic paper position disk.

- Using a number of water drops, eject the water from the syringe evenly across the entire filter paper, beginning in the center and working out to the border.

- Tilt the magnetic disc as needed to ensure that the water is uniformly distributed throughout the filter paper.

- The paper should be evenly wetted, with no dry spots or trapped air between it and the disc.

- Start the 2-minute timer after placing the magnetic disc with wetted paper face down on the area under test and pushing firmly into any curves or irregularities.

How to analyze the salt after it is extracted?

- After 2 minutes, take the filter paper and magnetic disc from the test surface and place them on the measuring electrodes.

- Close the lid and make sure the magnetic catch is fully engaged, the gauge will start measuring.

- The reading is displayed on the screen; take note of it.

- Remove the magnetic disk and filter paper by lifting the lid.

- Using purified water and a sensor wipe, clean the magnetic disk and measuring electrode.

The salt contamination meter measures the salt in what unit?

The salt contamination meter detects the concentration of salt in µg/cm2 or mg/m2. The coating inspector should change the measuring unit on the instrument so that the result is displayed in the desired unit.

What is the standard method for determining salt levels using SCM?

SSPC G15 is the most common standard test method by coating inspectors to measure the salt test using the salt contamination meter.

SSPC stands for the Society of Protective Coatings.

What is the maximum acceptable salt concentration on a surface?

Typically, the maximum salt concentration limit ranges from 20mg/m2 to 30mg/m2. The precise value varies according to the location where the coating is to be applied.

What happens if the salt concentration exceeds the maximum allowed?

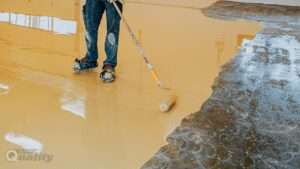

Typically, the surface that exceeds the salt level is water-washed with portable water and re-tested until the salt level falls to an acceptable level.

Conclusion (Salt Testing)

One of the most typical tests that coating inspectors carry out is the salt test, which ensures that the salt concentration on the surface to be coated is within the acceptable range. SCM or salt contamination meter is the frequently used method for extracting and analyzing salt from the surface to be coated in accordance with SSPC G15.

More Articles Related to Salt Testing

9 Information’s about Corrosion Under Insulation That Will Enhance Your CUI Skills

Training Courses that Enables you to Perform the Salt Testing

Fireproofing Inspector Level 2