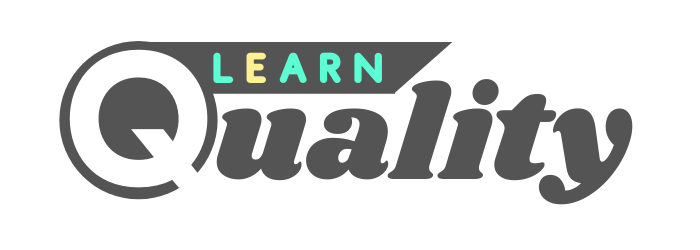

Are you interested in working for or already working in the thermal insulation field of an oil refinery or industrial processing plant? If so, you’ve come to the right place to learn more about thermal insulation. Here, we answer some of the most frequently asked questions about insulation and its use.

What is Insulation?

Essentially, it is any material or system used to resist or restrict the transfer of thermal energy or sound. Insulation material can reduce the flow of heat energy by reflection, absorption, or both.

A common misconception is that insulation keeps the cold out, when in fact the function of insulation is to reduce the transfer of heat, which means it keeps heat in. Heat energy will transfer to nearby objects of lower temperatures.

What is so special about insulation’s ability to prevent the loss of heat?

Thermal insulation material contains voids or hollow spaces that help resist heat transfer. Heat flows naturally from warmer areas to cooler ones. Insulation works by slowing that movement of heat from a hot space to a cooler space or vice versa.

What are the Different Categories of Insulation?

Insulating materials are divided into the following 4 categories:

- Fibrous

- Granular

- Cellular

- Reflective

The materials in each category have both pros and cons. It is your responsibility to understand them before you select a material for use in your project.

For example, insulation materials made of fiber are not suitable for resisting cold temperatures, but cellular materials have limitations for use at temperatures above ambient.

The insulation materials’ temperature ranges and their properties can be found in the product datasheet you receive from the insulation manufacturer.

How to Choose the Best Insulating Material?

Before choosing an insulating material for your project, be sure to answer the following commonly asked questions:

- What item requires insulation?

- Temperature limit

- Size or area

- Type of substrate to be insulated (i.e., metallic or non-metallic)

- What is the geographical location/environmental condition?

- What is the purpose of the insulation?

- Heat or cold conservation

- Sound prevention

- Personal protection

Decide the Right Insulating Material

Based on the answers to the above questions, you must decide the type of insulating material, thickness, and whether the installed insulation requires further protection from its surrounding environment.

Next, contact the insulation manufacturer to identify the insulation materials to best suit your requirements and/or review the material’s product datasheet to check which materials meet your requirement.

Finally, you must decide whether to use the accessories materials (i.e., fixing or fastening materials) to help keep the insulation in place around the insulating item. You must also ensure that all the fixing materials you use are compatible with the insulation, jacketing, substrate, and other fixing materials.

Write a Specification for the Insulation Work

Before commencing the insulation work, you must write a specification that details the material(s), their properties, and how the work will be carried for your project.

Next, find a contractor with a proven track record to carry out the insulation work for your project following the instructions and guidelines set forth in the specification and/or recommended by the insulation manufacturer.

What are the Different Types of Insulation Material?

There are several types of thermal insulation materials to choose from, including:

Mineral wool

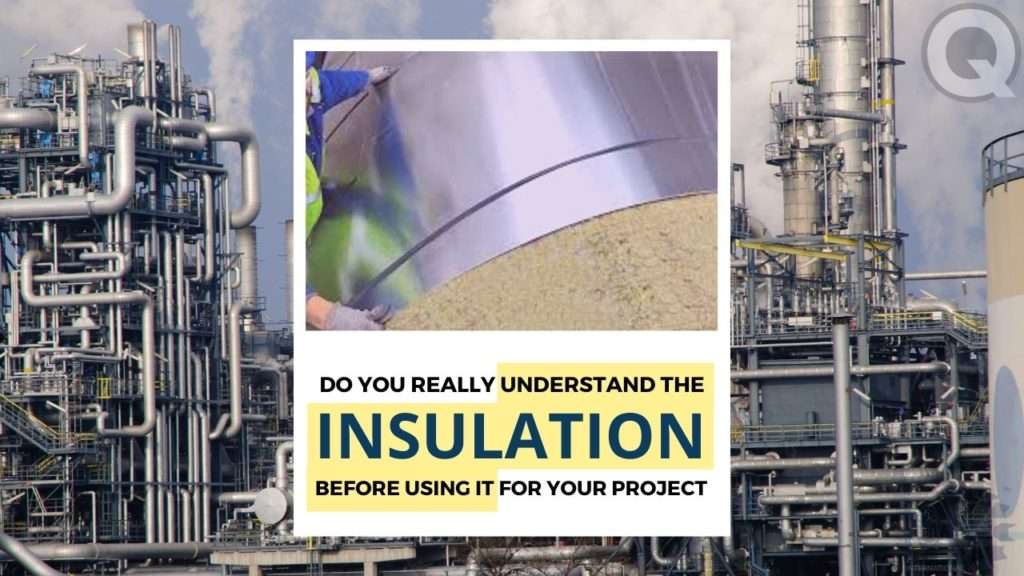

A fibrous insulation material made of rock or stone, used to resist high temperatures, also protect the environment from excessive noise.

Calcium silicate

A granular insulation material. This white-colored insulation, used to resist high temperatures.

Cellular or foam glass

Celluar glass and foam glass are the two different names of the same material. Made of recycled glass and is cellular or closed-cell insulation. The foam glass insulation is primarily used to resist cold temperatures; however, it can also be used for hot services up to 400˚C temperatures.

PIR

A cellular type of insulation, also known as polyisocyanurate insulation, is commonly used for cold surfaces because it has temperature limitations when used for hot ones.

Ceramic fiber

This fibrous insulation material is also known as high-temperature insulation wool (HTIW) and is often used for lining furnaces.

The 4 common properties of an insulation material

- Thermal conductivity

- Thermal Resistance

- Density

- Combustibility

Thermal conductivity, also known as the K value of the insulating material decides if a material is a good insulator or not. The lower the K value the better the insulation material is. The thermal resistance or R-value state how well an insulating material can resist the heat, R-value is opposite to the K-value, i.e. good insulation must have a higher R-value.

The density is mass per unit volume of a material. Combustibility means if a material will catch fire or not, non-combustible type material is a must in an area prone to fire.

Where will the Insulation be Used?

Insulation is used everywhere whether it is a home, office, appliances you use, or oil refinery or industrial process plant. some of the areas where you would find insulation are listed below:

INDUSTRIAL

Piping: When looking around a refinery or industrial processing plant, you will find yourself surrounded by insulated items. One such insulated item is piping. Approx. 75% (or more) of the piping used is insulated for a variety of reasons like hot or cold conservation, process control, personal protection, etc. A medium-sized oil refinery contains 475 miles of insulated piping.

Equipment: Equipment such as heat exchangers, boilers, columns, pressure vessels, storage tanks, pumps, and compressors, are all insulated for heat conservation, cold conservation, acoustic attenuation, or any other oil refinery or industrial processing plant purpose.

For your information, a medium-sized oil refinery contains 1.8 million square feet of insulated equipment.

DOMESTIC

Wall insulation: Walls are a major source of energy loss in homes, it is a must to reduce heat loss through the cavity wall by filling the air gap with material that interferes with heat transfer, trapping air in the cavity, thereby preventing heat loss and reducing heating costs.

Basement Insulation: The basement is another area of a home where there is a need for insulation installation. Basement walls are insulated with non-water sensitive insulation that prevents interior air from contacting cold basement surfaces.

Crawl space insulation: This space is often forgotten because not everyone uses their crawl space regularly; however, it can help prevent heat from leaking into or escaping from your home. The best insulation material for crawl spaces is a rigid foam insulation board.

Domestic appliances; Air-conditioning, refrigerator, water cooler, and the like are all insulated to prevent the movement of heat into or out of them.