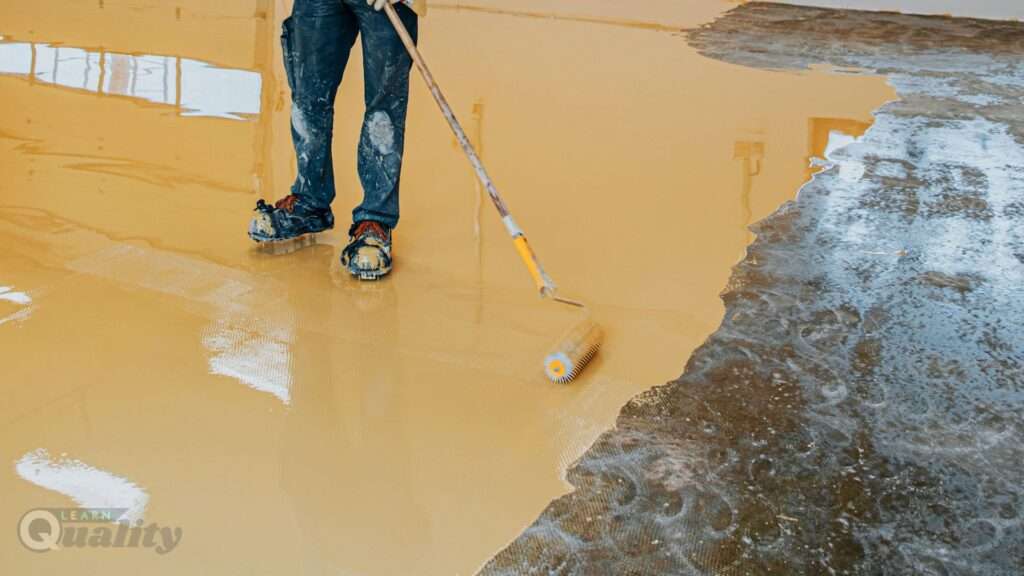

Concrete surface preparation for coating

Coatings are applied on concrete to provide a covering or aesthetic protection, hence extending the life of the structure or surface and lowering maintenance and repair expenses. Surface preparation is one of the important parts of applying any kind of coating to any surface. This article discusses the concrete surface preparation for coating. There are various surface preparation methods available for cleaning concrete which remove grease, dirt, and loose particles before applying coatings.

What are the options for preparing the concrete surface for coating?

The following are some of the methods that are often used for cleaning concrete for coating.

- washing the broom

- Cleaning with a vacuum

- Cleaning using compressed air

- Water purification

- Cleaning with detergent water

- Cleaning using steam

What exactly is surface cleaning or cleanliness?

Surface cleaning is a sort of cleaning that offers a clean, contamination-free surface without affecting the surface’s soundness or intactness. A clean surface is free of oil, grease, loosely adhering material, and other contaminants.

Cleaning the concrete surface with air, water, scrubbing, sweeping, or vacuuming are all suitable methods. If the concrete surface has oil and grease spots, cleaning solutions can be used to remove the spots, followed by a freshwater rinse.

Let’s get started and learn about the broom cleaning approach and how it helps clean the concrete surface.

Utilizing the broom cleaning method to prepare or clean concrete

Broom cleaning is one of the concrete cleaning methods used to remove surface dust and other weakly adhered solid contaminants. Sweeping the area with a clean industrial stiff-bristled broom or equivalent tool is what broom cleaning involves.

Surfaces that have been broom-cleaned require extra cleaning utilizing one or more surface preparation methods such as vacuum cleaning, air blast cleaning, water cleaning, detergent water cleaning, or steam cleaning.

Continue reading to learn about the next cleaning method for concrete.

Cleaning the concrete surface using a vacuum

The purpose of the vacuum cleaning method is to remove surface dust and other debris. Vacuum cleaning involves vacuuming the surface using a heavy-duty industrial vacuum to ensure a dust-free surface.

Continue reading to learn about the third concrete cleaning method, air blast cleaning.

Cleaning concrete with an air blast

The air blast cleaning method is designed to remove debris, dust, dirt, weakly adhered laitance, and concrete walls and ceilings while also providing a dust-free surface.

Cleaning the surface using a compressed air stream at 80 to 100 psi through a blasting nozzle held around 2 ft from the surface is what air blast cleaning involves.

When using the air blast cleaning option to clean the concrete, make sure the air stream is free of grease.

The ASTM D4285 standard test method can be used to ensure the purity of the air before it is used to clean the concrete.

Because air blast cleaning may produce air-borne dust before it is redeposited, vacuum cleaning may be required to remove redeposited dust from the concrete surface.

Continue reading to learn about the next cleaning method for concrete.

Water washing method for cleaning the concrete surface

Water washing is meant to remove dust, debris, and water-soluble surface contaminants from concrete. Water cleaning is the process of cleaning a surface using a stream of clean potable water at a high enough pressure to remove dust, debris, and loose material. Hand scrubbing with a stiff-bristled brush is also an option when necessary.

A provision should be provided prior to water washing for the removal of wash water and contaminants generated through this cleaning process.

Additionally, prior to applying coatings to a surface that has been washed with water, testing for moisture content in accordance with Test Method ASTM D4263 may be required.

If the concrete surface has oil or grease on it, detergent water cleaning is an alternative for cleaning; keep reading to learn more.

Cleaning with Detergent Water to remove oil and grease from the concrete surface

The detergent water cleaning method is meant to remove surface contaminants that are water-soluble, as well as oils, grease, and other emulsifiable compounds.

Scraping off large deposits of grease or oil before cleaning the surface with a stiff-bristled brush and an aqueous solution of detergent or a nonsolvent emulsifier is also helpful.

This is to note that the cleaning agent residues must be eliminated immediately after treatment, before the surface dries, by thoroughly rinsing the surface with clean potable water.

The flushing process must be repeated until the pH of the surface water matches the acceptance standards given in ASTM D4262.

Following the manufacturer’s recommendations, trisodium phosphate at not less than 4 oz/gal or proprietary solutions intended for cleaning concrete may be used. The use of hot water may increase the effectiveness of trisodium phosphate.

The above-mentioned cleaning procedure should be performed until water does not bead on the concrete surfaces.

Additionally, preparations must be established prior to detergent water washing for the removal of wash water and contaminants generated by the detergent water cleaning procedure.

The cleaned surface can also be checked for moisture content using the ASTM D4263 Test Method.

Continue reading to find out more about the next cleaning method, steam cleaning.

Cleaning concrete using a steam cleaning method

The steam cleaning method is comparable to detergent water washing, however, it is more successful at removing thick grease and oil deposits.

Steam cleaning is the process of cleaning a surface with a jet of high-pressure steam that is strong enough to eliminate impurities.

Detergents or nonsolvent emulsifying agents designed for use with steam cleaning equipment may be added where Oil and grease cleaning is essential.

When detergents or other emulsifying agents are employed, the surface is completely flushed with potable water after cleaning and before it dries. To remove cleaning residues, additional flushing may be required.

Prior to applying coatings and following steam cleaning, surfaces cleaned with detergent or nonsolvent emulsifying agents must be evaluated for pH in accordance with ASTM D4262 and moisture content in accordance with ASTM D4263.

Prior to steam cleaning, plans must be established to remove the water and toxins produced by this cleaning procedure.

Now that you’ve learned about the many ways to clean the surface of concrete, the next step is to learn how to inspect the concrete surface after it’s been cleaned, so keep reading.

Inspection and testing before applying coating on the concrete surface

After cleaning with one of the methods indicated above, the coating inspector should visually evaluate the prepared and cleaned surface for the presence of debris, dust, dirt, oil, grease, loosely adhered concrete, and other impurities.

The coating inspector should also check for pH following the Test Method ASTM D4262 on surfaces cleaned with detergent or nonsolvent emulsifying agents, and if there is a possibility for moisture content on the cleaned surface, ASTM D4263 may be used to test the surface.