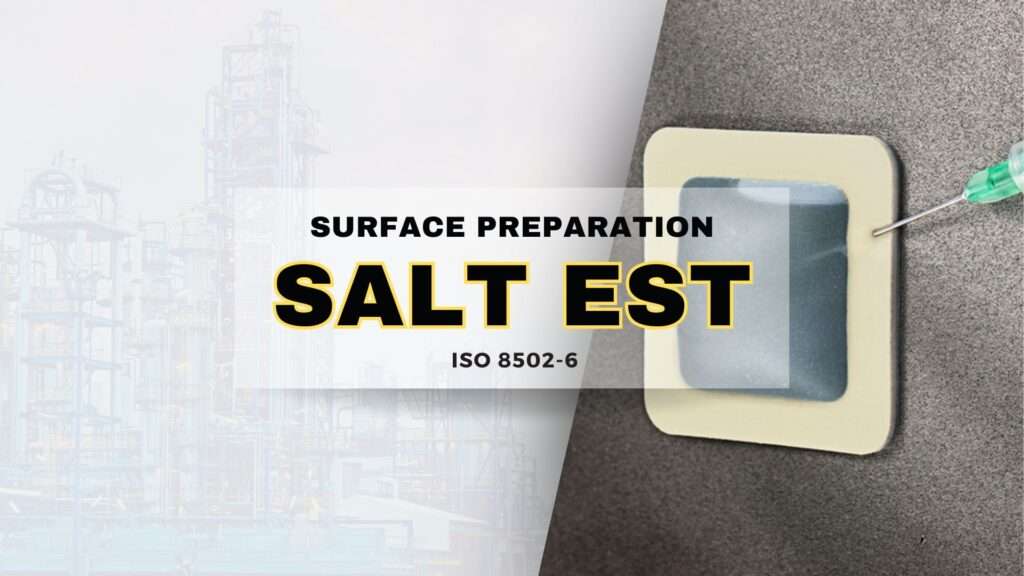

Water Soluble Salt Test using the Bressel Patch Method and Conductivity Meter (ISO 8502-6)

One of the most common tests done after the surface has been prepared for coating application is the water soluble salt test. A project coating specification includes the allowable salt limit, and it is the coating inspector’s duty to perform the water-soluble salt test according to the test method indicated in the specification to ensure compliance.

There are several salt test methods available, however, the most accurate test method is the bressle patch test method performed in line with ISO 8502-6. This article provides you with an overview and the necessary knowledge to execute the water soluble salt test in accordance with the standard above.

Water-Soluble Salt Test Principle

The bressle patch includes a central compartment that holds the distilled or deionized water. The patch is attached to the surface to remove the soluble contaminants. The water is injected into the compartment by means of a syringe and then sucked back into the syringe.

Injecting water and sucking it back to the syringe is repeated a number of times. The water is then transferred to a suitable vessel for analysis.

What a bressle patch is?

Bressle patch is a flexible material with closed pores and a hole punched in the center. The punched-out material serves as reinforcement in the hole until the patch is applied. A thin elastomer coating is applied to one side of the patch. The other side is adhesive-coated and protected by a removable paper protection layer.

Type and Size of the syringe to be used for the salt test

A common type of reusable syringe with the maximum cylindrical value of 1mm, 8mm, and 50mm is used.

Type of water to be used for the water soluble salt test

For the determination of water-soluble salts or contaminants, the use of distilled or deionized water is popular.

What conductivity meter is

The conductivity meter is an instrument that is used to measure the conductivity of the water.

Water Soluble Salt Test Procedure

- Take a bressle patch from the kit and peel away the protective paper and punched-out material to perform the water-soluble salt test.

- Press the patch’s adhesive side on the test surface in a way that a small amount of air is trapped in the patch’s compartment.

- Fill the syringe with 2 ml of distilled or deionized water.

- Insert the syringe needle at an angle of about 30° to the test surface near the patch’s outer border, such that it passes through the adhesive foam body of the patch into the compartment formed between the elastomer film and the test surface.

- Inject the water from the syringe, making sure to wet the whole test surface. If necessary, and to avoid trapped air in the patch compartment, perform the injection in two steps as follows:

- Inject around 1ml of water into the patch, then expel the air through the needle with the syringe in reverse. Take the needle out of the patch. Expel the air while holding the syringe with the needle facing upwards. Reinsert the needle into the compartment and inject the remaining water.

- Suck the water back into the syringe after an appropriate amount of time (typically 1 minute). During this time, re-inject the solvent into the compartment and then suck the solvent back into the syringe cylinder at least four times without withdrawing the syringe needle from the patch.

- The extracted solution should then be transferred to a suitable vessel for analysis.

Note: This is to ensure that no water is lost from the patch or syringe during the sucking and re-injection of the water, for example, due to poor quality materials or inappropriate handling of the materials. If any solvent is lost, the resultant solution should be rejected.

To re-use the syringe, clean and rinse it.

How to check the water conductivity with a conductivity meter for salt test

- Make sure that the conductivity meter is in good working condition and has a valid calibration.

- Turn ON the meter and verify the settings then verify its accuracy·

- Check that the conductivity meter is in working condition and that the calibration is valid. Turn on the meter, navigate to the settings menu, and then check its accuracy by pressing the ‘CAL’ button on the menu.

- Fill the electrode of the conductivity meter with the calibration solution provided by the instrument manufacturer.

- Hold down the calibration button until the instruments’ screen displays the solution reading. Check that the reading corresponds to the known conductivity of the solution.

- If the instrument reads the known value of the solution, the conductivity meter is ready for measurement of the solution extracted from the bressle patch; if it does not read the known value, calibration of the conductivity meter according to the manufacturer’s recommendations is required.

How to measure the salt from the extracted solution from bresle patch

- Drop the extracted solution into the conductivity meter electrode to cover it completely. Check the solution’s conductivity by looking at the screen of the conductivity meter and record the following results:

- Conductivity of solution

- Temperature of solution

- Surface density of soluble salts)

Related Video