Every product developer wants it to get into the hands of the right consumers. However, this depends on how well they can manage and ensure the quality compliance of the product. This is where ‘Product Inspection’ and ‘Product Testing’ come in.

Contrary to the popular view, there is a difference between ‘Product Testing’ and ‘Product Inspection.’ As you will find out in this article, each entails different things. Plus, there are different factors to consider when deciding how best to go about Inspection and Testing for your product.

How is Product Inspection different from Product Testing?

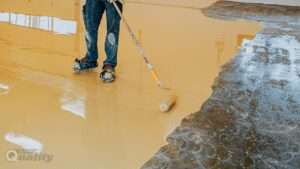

Product inspections entail the verification of the product’s quality at different levels of the manufacturing process. The process is handled by Quality Control Inspectors, who assess random samples of the product to confirm that the actual function and appearance do not contradict the specified requirements.

Such assessments might include measuring the product, checking and confirming color matches with the samples, and ensuring it works as expected. Others include checking for the presence and accuracy of barcodes and labels (if any).

Product inspections aim to detect defects or flaws in quality before dispatching the product to the end-users. It is best to contact a third party for a product inspection – they are better equipped and impartial in their findings.

Product Testing, on the other hand, entails conducting laboratory tests on the product to see if it complies with the relevant regulations and standards. For instance, the compliance of a garment to flammability standards, or the presence/absence of lead paint in plastic toys, might be tested.

Only certified laboratories are equipped to undertake product tests. Testing also helps to ascertain the safety of the raw materials used in the production process, making it easier to detect possible safety risks associated with the product.

How do product inspections work?

Every construction or manufacturing company is expected to have a team of internal quality control inspectors. This team is usually responsible for assessing the quality of the product. However, such a team still somewhat answers to the factory management.

If you are an importer or end-user, it is best that you put additional measures in place to ensure product quality. This is where third-party inspections come in.

What are third-party inspections, and how do they work?

While there are various kinds of inspections, the hold and witness point inspection is the most popular. In this type of inspection, the inspector is present on the job site or factory, where they conduct multiple checks from the inspection checklist in line with the inspection and test plan.

These checks include packaging and labeling, product function, physical requirements, and others. At the end of the inspection, they provide an inspection report that details their findings.

Why Product Testing?

Lab testing or product testing simply means subjecting your products and raw materials to the standard tests at a certified, independent laboratory. You can do product testing either during pre-production or after mass production.

Like product inspections, doing product testing early can save you from issues that can cripple the production line. Asides from this, it comes with product safety and performance certification.

There are different types of tests, each suited to a different product type and the industry standards associated with such product. It is essential to be very conversant with the product you are dealing with, the proposed use and users, and any other associated standards. If you are in the United States, you can check out the Customer Product Safety Commission (CPSC) for some useful resources on this.

Another important factor to consider during product testing is the credibility of the laboratory. As mentioned earlier, only accredited, certified laboratories should be used for product testing. Such laboratories must have an ISO 17025 certification or be listed as an accepted testing laboratory in your users’ countries. This is another way of ensuring the safety, quality, and regulatory compliance of your products.

Product Inspection and Testing are collectively crucial

Although they are two distinct processes, importers must understand that product Inspection and Testing are crucial to their quality control and compliance efforts. This is why only certified quality control inspectors or independent and accredited inspection bodies should handle both processes.

Individual Certification in Inspection and Quality Control

Quality control is an essential concept in total quality management. It involves the establishment of the observation activities and techniques to meet the quality standards an organization requires.

A quality control inspector oversees the quality control process. This professional is usually appointed to carry out the standard checks associated with quality control, record their findings, and provide daily, weekly, or monthly reports.

Any organization that effectively implements the QMS will hire well-trained, certified, and experienced quality control personnel to oversee the inspection and testing work. There are several recognized training and certification courses a quality control personnel is expected to undertake.

Here are a few of such courses for an aspiring quality control inspector in the oil and gas sector:

- NACE (National Association of Corrosion Engineers)

- SSPC (The Society for Protective Coating)

- IOGS (The Institute for Oil and Gas Sector)

- TWI (The Welding Institute)

- API (American Petroleum Institute)

Each of these quality control courses runs for various durations and attracts different fees. Participants can opt for either classroom learning or online learning. After completing the studies, the participants are awarded the necessary certifications as quality control inspectors. However, having a degree or diploma and some relevant experience in the work field will increase their chances of landing their dream jobs in the job market.